JET SYSTEM CONTROL AND CONFIGURATION SYSTEM

THE WORLD’S MOST ADVANCED HAZARD MONITORING SYSTEM

JET SYSTEM, THE SMART WAY TO MANAGE YOUR SAFETY SYSTEM

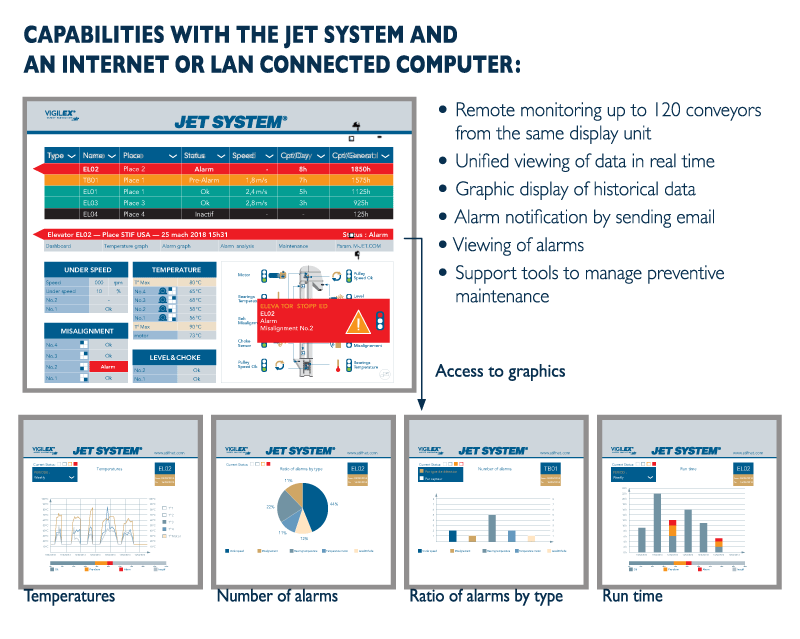

This configuration of the system gives complete control and feedback of your conveyors and elevators avoiding all associated hazards associated with under speed, misalignment, level & choke control, bearing and motor temperature which are the main ignition sources in explosion risks. By notifying you directly on the defects and performance via your laptop, tablet or mobile phone you can effectively manage your plant anywhere on the globe ensuring your operation remains efficient with reduced downtime.

-

1. M-JET+ or M-JET monitors the following

- Under speed due to belt slip on the pulley (checked by comparing with the nominal speed)

- Bearing temperature using sensor PT100 or NTC

- Belt misalignment using sensors with or without contact

- Material jam in conveyor entry or exit using capacitive sensor

- Chain elongation measured by inductive sensor and targets

- Motor power measurement with specific electrical consumption

- Shaft position measured by 4–20mA sensor

-

2. Operating Control of the System (Output Relays)

- Directly on the power relay of the motor

- By the global PLC of the facilities

-

3. Verifying Conveyor Operation

- On the computer screen via internal website (directly with laptop or via Network LAN)

- By message to the email inbox (events and maintenance operation plan)

THE HAZARD MONITORING DEVICES ARE ABLE TO MONITOR BUCKET ELEVATORS, BELT CONVEYORS, CHAIN CONVEYORS AND SCREW CONVEYORS

Our hazard monitoring system analyses the data sent by the sensors installed on the equipment and save the eventual defects events. According to the setting, the M-JET+ or the M-JET sends alarms and commands the stopping of the conveyor.